Cognitive Agro Pilot

YOUR AI-BASED CROP-HARVESTING ASSISTANT

INVEST IN NEXT-GENERATION SOLUTIONS

*Will be available in the 2022 harvest season, may require additional equipment.

AUTONOMOUS DRIVING MODES

1

1

2

2

3

3

Imagine a combine that doesn’t blindly follow a virtual line across a field but switches to unharvested areas, changes its route autonomously, and sends new information to other machines.

It can harvest any crop in any configuration, by following the crop edge, a windrow, or a crop row.

No complex settings required: Agro Pilot automatically detects unharvested areas, plots a route accordingly, and selects an appropriate harvesting mode.

An obstacle in the way?

The combine stops, makes a detour, or requests assistance from the operator. This protects the machinery and people’s health, as well as saving time and money.

Cognitive Agro Pilot use case

Splitting driving and control of harvesting equipment between robot mode and a human operator.

Analysis of yield maps and harvesting modes for next-season planning. Reduction in mechanical incidents and protection of hardware for a longer service life.

Up to 5% reduction in fuel consumption during harvesting.

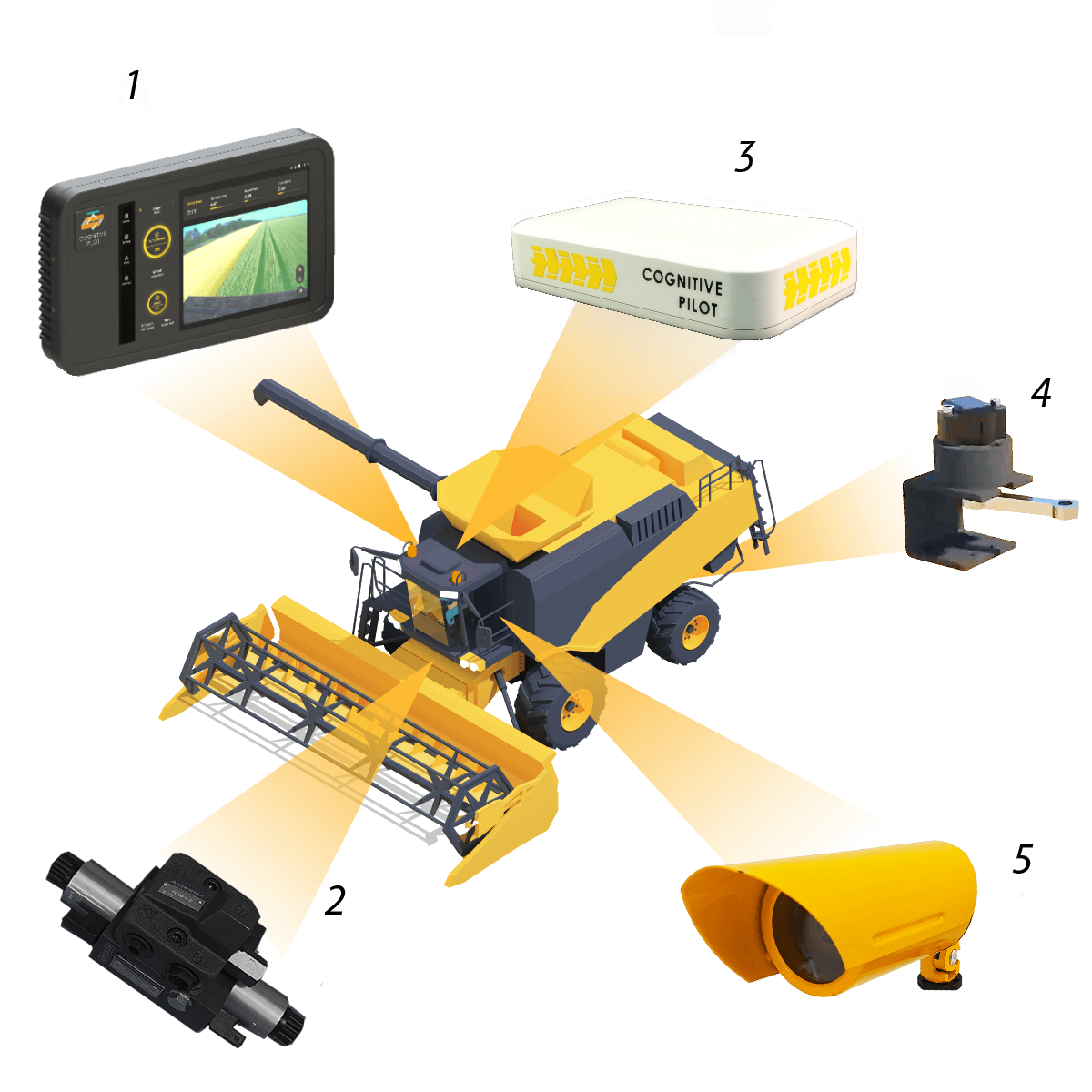

- Control unit with neuroprocessor and control display.

- Digital hydraulic unit for steering.

- Communication and navigation module.

- Steering angle sensors.

- Armored color video camera.

Maximum use of land resources and optimization of costs.

*Will be available in the 2022 harvest season, may require additional equipment.

The Agro Pilot system takes only a day or two to install and launch on any grain harvester – no wasting time on configuration and maintenance.

The system software can be configured and updated through the user application. Field maps do not require updating or charting.

It depends on the size of your field and the number of combines. In our practice, an average enterprise can save from two to four days per season.

As of June 1, 2020, Cognitive Agro Pilot is compatible with all types of grain harvesters. We plan to introduce the suite for other crops in the spring of 2021.

In a nutshell, parallel driving means navigating in the dark. For such a system to operate, it needs a steady GPS signal and a subscription to RTK corrections (about $70 a month). Before starting, a parallel driving system takes 10 to 15 minutes to “warm up” and latch onto the signal. When the combine is in motion, the stability of the navigation signal varies. This affects the accuracy of navigation, which can vary from 5 cm to 50 cm. In the course of harvesting, such fluctuations result in narrow strips of unharvested crops, which you have to either leave in the field or to go back to harvest at the cost of using extra fuel. However human operators remain the “eyes” of a system like this, and all obstacles remain their responsibility.

By contrast, Cognitive Agro Pilot “sees” and “understands” its surroundings in real time: the crop edge, a windrow, a crop row, or any obstacles ahead. As a result, the driving is done in the same way as a human operator does it, with consideration to the real location of objects along the route. The operator, therefore, can focus on the harvester.